Technical Tours

Toronto 2024 offers a wide range of technical tours. By joining the technical tours, you will enjoy a more comprehensive and hands-on experience as part of the Congress. Participants can choose among a range of different excursions and site visits in and around Toronto. Don’t miss this unique chance to visit some of the most significant water landmarks and treatment plants in Ontario! More information on how to reserve the tours, any additional costs and precise dates for each tour will be confirmed soon – watch this space for updates.

Scroll down and click on the description to learn more about the individual tours. Each tour has different timings, so check carefully when planning your schedule. Please note that most of the tours require closed toe shoes for safety reasons.

All tour tickets are £41 GBP and can be purchased during or after registration for the event.

Technical Tour 2 – Hespeler and Elmira MABR

Time: 8:30 to 17:00

PAX: 50

Closed toe shoe and long pants required

Lunch at the market $

Membrane Aerated Biofilm Reactors (MABR) integrate biofilms with semi-permeable membranes that facilitate the diffusion of oxygen directly from air in a compact and energy efficient technology. The MABR technology is particularly effective at removing nitrogen from wastewater. The biofilm process promotes the conversion of ammonia into nitrate and in some configurations can also support denitrification.

Waterloo Region has recently installed the MABR technology at two full scale wastewater treatment plants (Hespeler and Elmira). These facilities are amongst the largest MABR installations in the world and include technologies from the two largest suppliers of the technology. This tour will provide attendees with an opportunity to learn from the technology vendors, see the equipment in operation and talk to the plant operators.

The tour includes visits to the two full-scale operating MABR facilities and a visit to St. Jacobs Ontario. St. Jacobs is famous for its farmers’ market and the St. Jacobs Village, which attract both locals and tourists. The market features a wide range of locally grown produce, artisan crafts, and homemade goods, many of which are produced by Mennonite families. Tourists visit the area to experience the Mennonite culture, purchase handmade products, and learn about the community’s history

Technical Tour 5 – Arthur P. Kennedy Water Treatment Plant + Veolia

Time: 8:30 to 14:30

PAX: 45

Closed toe shoes

Lunch included

This is a combined tour of the membrane system supplier (Veolia WTS) and Arthur P. Kennedy WTP.

The Region of Peel has two water treatment plants, Arthur P. Kennedy (APK) Water Treatment Plant (formerly known as Lakeview) and Lorne Park WTP, both located in the City of Mississauga in Canada. The water supply for both plants comes from the northern shore of Lake Ontario.

APK is one of the world’s largest ultrafiltration membrane plants. The compact plant footprint allows for the preservation of green space around the plant and allows for the continued use of Region property at the site for public recreational purposes. It has the treatment capacity to produce 1200 million litres (3x400MLD trains) of clean water every day for residents in the eastern part of Mississauga and Brampton, and the community of Bolton and York Region. APK is comprised of three treatment trains: a 400 MLD Conventional filtration train with downstream Ultraviolet Reactors, a 400MLD Ozone/Biologically Active Carbon Contactor/Membrane (OBM1) train, and a 400MLD Ozone/Biologically Active Carbon Contactor/Ultraviolet Reactors/ Membrane (OBM2) train. Ozone and BAC provide pretreatment for the raw water prior to UF. The selected treatment train provides multiple barriers for disinfecting the water supply, for controlling its taste and odor, and for removing turbidity.

Veolia Water Technologies & Solutions Canada (Oakville, Ontario) is the water and wastewater centre of Veolia WTS, which has 600 employees, including water and wastewater process engineers, application engineers, project engineers, product management and development, marketing and technicians for service and pilot testing. This site has a pilot shop, R&D facility, membrane museum and on-site water and wastewater MBR treatment system that recycles treated effluent within the building.

Technical Tour 6 – Disco Road Resource Recovery Facility

Time: 8:30 to 12:00

PAX: 45

Closed toe shoe required

The state-of-the-art Disco Road Organics Processing Facility uses innovative pre-processing and anaerobic digestion technology to break down organic material to produce: digester solids, which are used to create high quality compost, and and biogas, which the City is upgrading into renewable natural gas (RNG) and blending with the natural gas it buys to create a lower carbon-fuel blend that can be used to fuel City fleet and heat City buildings. It processes 75,000 tonnes of organics per year using a state-of-the-art wet pre-processing system and anaerobic digestion. Organic material is pre-processed in a hydropulper where it is mixed with water to facilitate the removal of the non-organic materials. This is followed by anaerobic digestion. This facility is North America’s first full-scale municipal source-separated organics/green bin waste processing operation to use anaerobic digestion. It includes a sophisticated odour control system, incorporates the harvesting of rainwater and uses biogas in dual-fired boilers to meet processing demand and help heat the building.

Technical Tour 7 – Ashbridge’s Bay Wastewater Treatment Plant

Time: 9:00-13:00

50 PAX

Closed toe shoes required

Rated at 818 ML/d, the Ashbridges Bay Wastewater Treatment Plant is Canada’s largest secondary wastewater treatment facility. This site has been under construction for the last 50 years and its new influent wastewater pumping station currently under construction will be one of the largest in in the world. Major liquid treatment processes include screening and grit removal, primary treatment, secondary treatment, nutrient removal, and effluent disinfection. Treated effluent is discharged to Lake Ontario. Solids handling processes include waste activated sludge thickening, sludge stabilization by anaerobic digestion, dewatering using high speed centrifuges and biosolids management. The plant also provides production of biosolids for beneficial use, including the biosolids that are generated and transferred from the two other City of Toronto WWTPs. Tour will include an overview of facility, long construction history, time-lapse video, new outfall and UV disinfection system, stormwater management work to better manage flows to the plant, biosolids management, pelletizer, odour control, landform development.

Technical Tour 8 – Lorne Park Water Treatment Plant + Veolia

Time: 8:30-14:30

PAX: 45

Closed toe shoes required

Lunch included

This is a combined tour of the membrane system supplier (Veolia WTS) and Lorne Park WTP.

The Region of Peel has two water treatment plants, Arthur P. Kennedy Water Treatment Plant (formerly known as Lakeview) and Lorne Park WTP, both located in the City of Mississauga in Canada. The water supply for both plants comes from the northern shore of Lake Ontario.

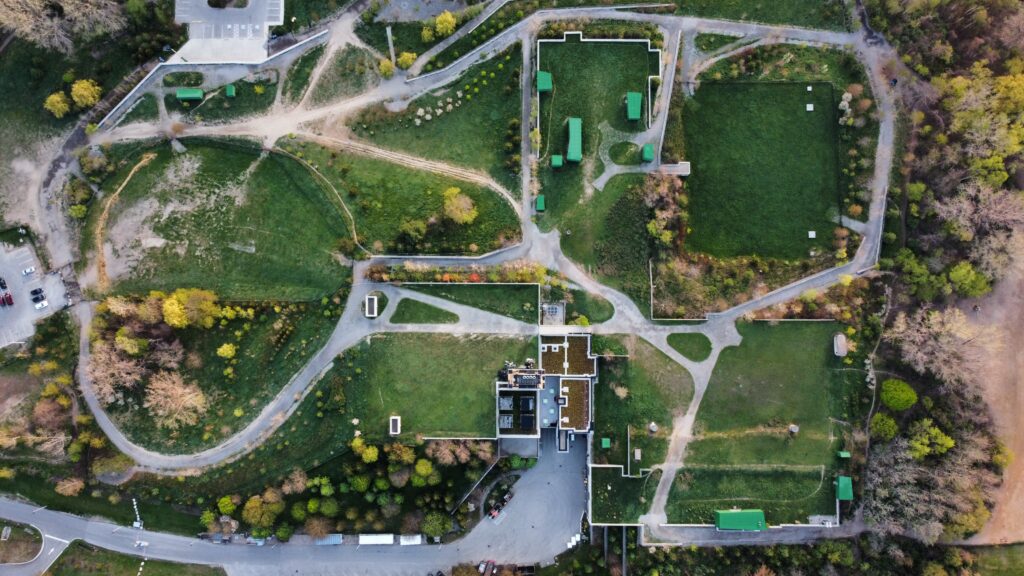

Lorne Park WTP is a unique facility as it resides fully under a municipal park that is accessible to the public. It is the largest retrofitted low-pressure municipal membrane filtration system in the world and hosts the largest municipal UV advanced oxidation installation for taste and odour removal in North America, and one of the largest in the world. It consists of two treatment systems: a 120 MLD Conventional filtration train and a 380 MLD Membrane/Ultraviolet Reactors/Granular Active Carbon Contactor (MUG) train. With minimal additional footprint, the plant is equipped with state-of-the-art technology and processes that provide a high level of removal and inactivation of pathogens, and control taste and odour compounds that occur seasonally.

Veolia Water Technologies & Solutions Canada (Oakville, Ontario) is the water and wastewater centre of Veolia WTS, which has 600 employees, including water and wastewater process engineers, application engineers, project engineers, product management and development, marketing and technicians for service and pilot testing. This site has a pilot shop, R&D facility, membrane museum and on-site water and wastewater MBR treatment system that recycles treated effluent within the building.

Technical Tour 10 – Walkerton Clean Water Centre

Time: 8:00-18:30

PAX: 50

Closed toe shoes required

Lunch included

Discover the Walkerton Clean Water Centre (WCWC) — where we educate and support utilities, operators and owners as they safeguard water resources across Ontario.

Safeguarding Ontario’s Drinking Water

WCWC is an agency of the Government of Ontario, established in 2004, to help safeguard water resources. WCWC coordinates and delivers education and training for water system owners, operators, operating authorities and First Nations communities, including hands-on, correspondence and e-learning options. WCWC also provides information through pilot tests, with a focus on systems in small and First Nations communities.

A World of Water Knowledge

Our training programs, including hands-on and e-learning options, have provided valuable education to more than 100,000 participants across Ontario. WCWC also supports operators and managers of First Nations drinking water systems in their efforts to improve drinking water, and through partnerships, provides training for First Nations communities across Ontario. WCWC also maintains a Drinking Water Resource Library where water professionals and the public can access fact sheets, how-to videos and reference documents.

Conventional and Advanced Water Treatment Technologies

WCWC’s Technology Demonstration Facility displays conventional and advanced water treatment technologies and distribution systems, such as an automated dual-train conventional treatment plant, dissolved air flotation, ozone disinfection pilot, an innovative MIEX ion-exchange system, and membrane filtration systems.

Join us for a tour all about drinking water!

Technical Tour 11 – Horgan Water Treatment Plant & Highland Creek WWTP

Time: 8:00-16:00

PAX: 50

Closed toe shoes required

Lunch included

Join us for a full day tour of a water and wastewater facility at the City of Toronto. The Horgan WTP is a direct filtration plant rated at 800 ML/d. The plant underwent a 230 ML/d expansion between 2009 and 2013 that included the addition of ozone for disinfection and taste and odour control to treat the full plant capacity as the first treatment step, modifications to coagulation and flocculation systems, addition of 5 new deep bed biological filters and extensive modification to the high lift pumping station to incorporate additional functionalities and isolation capabilities. The plant is located on the Scarborough bluffs which provides for a unique design of the low lift pumping station as the plant is located substantially higher than the lake water level. As part of the tour, attendees are taken several stories below lake level, showing off a unique and effective building design.

The Highland Creek WWTP is rated at 219 ML/d. It is built on either side of the train tracks with underground tunnels joining the two sides of the plant. Major treatment processes include preliminary treatment, primary treatment, secondary treatment, phosphorus removal with ferric sulphate/ferrous chloride, final effluent disinfection using sodium hypochlorite, and final effluent dechlorination using sodium bisulphite. Treated effluent is discharged to Lake Ontario. Solids handling processes include Waste Activated Sludge Thickening, sludge stabilization by anaerobic digestion followed by dewatering using high speed centrifuges. Two multiple hearth incinerators are used for the disposal of the dewatered biosolids – these are being replaced with fluidized bed incinerators.

Technical Tour 12 – Markham District Energy

Time: 8:45-12:00

PAX: 25

Closed toe shoes required

Markham District Energy (MDE) is a district energy provider located in the City of Markham. MDE has two district energy systems, supplying heating and cooling services to nearly 15 million sq.ft. of buildings from a series of four central utility plants.

During this tour, attendees will learn about how thermal and electrical energy is produced onsite with a look at the control room and equipment, including boilers, chillers, cogeneration units, and thermal storage tank. Participants will get to experience more innovative equipment as well, including a new heat recovery heat pump and biomass boiler, representing the future of MDE’s low carbon operation.